Water-related technologies developed in recent years are improving efficiency, treatment, utility operations and more. These technological advances have already had an impact on water use and point toward future innovations.

NASA Water Recycling Technologies Have Earthbound Uses

by Lucero Radonic, WRRC Graduate Outreach Assistant

A search for advanced filtration water bottles at any online retail store will come back with various product options, many of them made possible by NASA-derived technologies. “Spinoffs” is the term used to refer to technologies that were developed by NASA for its space explorations and later adapted and commercialized for everyday use on Earth. Since the 1960s, when NASA first began to develop water purification systems for the Gemini program, technologies for water recycling and purification have taken off.

The first successful spinoffs came from Apollo-era technology. In preparation for lunar missions, in 1968 NASA developed a small lightweight water purifier the size of a cigarette pack that was designed for minimal power consumption and monitoring. This chlorine-free device dispensed silver ions into the water supply to kill off bacteria. A private company, Carefree Clearwater, Ltd. from Georgia, was later given permission by NASA to manufacture a modified version of the Electrolytic Silver Ion Cell for commercial and industrial applications. The commercial system passes a small electrical current through copper and silver electrodes, releasing ions into the water. The ions kill bacteria and algae in the water by breaking down their enzymes, and the ions and dead organisms are then filtered out. Independent studies show it to be effective against pathogens like E. coli, Pseudomonas, Staphylococcus, Streptococcus and Salmonella. This purification system is used today in swimming pools, hot water spas, cooling towers, decorative fountains, ponds, manufacturing processes, and evaporative water cooling towers. Less chlorine in the purification system means less eye irritation, less dry skin, and a reduced exposure to carcinogens.

NASA’s Space Shuttle program, which requires a longer-lasting water purification system for its multi-week missions, has had more influence on the development of commercial technologies for drinking water purification. In the mid-1970s, NASA developed a water purification system that used iodine, rather than chlorine, to kill bacteria. Since then, water for the Space Shuttle Orbiter has been disinfected by a unit that passes water through a bed of iodinated resin known as a Microbial Check Valve (MCV). The original MCV cartridge had limited life, requiring periodic replacements. Continued research led to the development of the Regenerable Biocide Delivery Unit, which regenerates cartridges in place without removing them from the unit. This improvement of space technology constitutes a significant advancement in water purification, and is useful for pressing needs on Earth. The use of iodine provides an effective disinfectant and eliminates the hazards associated with chlorine. In addition, regenerability reduced the cost, ultimately to perhaps less than one cent per gallon, compared with $1 to 2 per gallon for bottled water, which makes it attractive as an emergency backup system for use during power outages, floods and other natural disasters.

In 2003, Seldon Laboratories LLC received a NASA Small Business Innovation Research (SBIR) award for a Nanomechanical Water Purification Device. Seldon patented Seldon Nanomesh, a lightweight, low-pressure water purifier that uses carbon nanotubes to remove waterborne viruses and bacteria quickly from large quantities of water. This system reduces the power requirements of closed-loop water treatment systems developed a decade earlier and successfully removes pollutants. The commercial version of the carbon Nanomesh designed under the NASA SBIR agreement was later released as WaterStick. This handheld, lightweight water purification system operates like a straw and is able to clean about 5 gallons (200 milliliters) of water per minute by using water pressure and gravity. Ease and portability makes this new line of spinoff water technology useful for accessing clean water in remote locations or disaster areas, where electricity might not be available.

A most recent innovation with great potential for future applications is the closed-loop water recycling system. In 2009, NASA gave the crew on the International Space Shuttle (ISS) authorization to drink the water purified by the station’s new water recycling system. This was the first time water was recycled in a closed-loop system and made available for human consumption. Since that time, ISS has used distillation technology, an absorption bed, and a catalytic oxidation reactor to treat urine and condensate water to generate potable water. The equipment was developed to operate in microgravity, while being simple enough that it can be repaired by the astronauts and maintained in orbit.

As NASA gears up for a future mission to Mars, which would take about two years, it continues to explore new water-recycling and purifying technologies that could support such a mission and address some Earthly water concerns.

Oro Valley Adopts Smart Metering

by Shirley Seng, Town of Oro Valley, AZ

Smart metering is the wave of the future in improving the operating efficiency of water utilities, and the Town of Oro Valley, Arizona is catching the wave. Smart meters permit timely meter reading from remote locations, eliminating meter reading errors, increasing labor efficiencies, and providing early leak detection. Oro Valley began implementing Advanced Metering Infrastructure (AMI) along with a water meter replacement program in 2011. AMI equipment includes smart meters, smart point transponders, a computer server, antennas and base stations. Meter readings are transmitted from smart points to an antenna. The antenna then transmits that data to a base station and ultimately back to a dedicated computer server in the utility’s office. The Town’s AMI equipment allows Water Utility personnel to read meters from the office instead of manually reading them in the field.

The Town’s initial project replaced 2,200 aging water meters in a satellite water service area about 10 miles from the Town’s main service area. Personnel monitored and analyzed metering data for two years to evaluate the effectiveness of the technology. Results from the initial project showed a 4 percent reduction in unaccounted-for water and a 57 percent reduction in the volume of water credited for leak adjustments. The test installation also reduced the number of trips made by service personnel to the area by 56 percent, resulting in a gasoline savings of $2,300 per year. In addition, the reduced traffic on residential streets provides a safety benefit.

The implementation of AMI has significantly improved customer service provided by the Town’s Water Utility. AMI water use data is transferred to a secure site that customers can access via a web portal known as AquaHawk. They are now able to view their water use on an hourly, daily, weekly, monthly or annual basis. Customers can set billing thresholds that, if exceeded, will trigger an alert sent via text, email or telephone, depending on their personal preference. The AquaHawk web portal can be viewed by customers anywhere they have internet access, making it a valuable tool for those who spend long periods of time out of town. The Town offers this web portal free of charge.

Early leak detection capability is a significant benefit of using AMI. The software associated with AMI allows Utility personnel to monitor for leaks on a daily basis. Customers are notified within 24 hours of a potential leak. This gives them an opportunity to repair the leak right away, resulting in savings of water and money. Conservation staff use this information to assist with water audits by educating customers about their specific water use.

With the elimination of manual meter reading, billing dates are no longer impacted by the day of week, holidays, weekends, or staffing. AMI allows the Water Utility to bill its customers on the same day every month, resulting in consistent water bills. This is important because the Utility uses increasing block rates to encourage conservation. Customers want to be certain that they have not tipped into a higher block rate because of a billing delay caused by a holiday.

The availability of AMI data facilitates the use of iPads by field personnel, which improve scheduling and customer relations. Daily work orders are emailed to Utility operators who then map a route for the most efficient travel plan. Through the use of Facetime on their iPads, supervisors can now support their staff without having to be at the same location. Field personnel also have access to the AMI data, as well as the billing and web portal software, allowing them to interact with customers on a new level. When responding to a customer inquiry in the field, personnel have the ability to show customers their water usage on a graph.

The Town is continuing with the AMI and meter replacement project throughout its entire water service area. The project is being completed in phases and is expected to be finished before July 2016.

In the future, the Town of Oro Valley will be incorporating water use data from AMI into its GIS mapping, hydraulic modeling and SCADA systems—the systems that handle the automated operation of the Water Utility’s infrastructure. AMI will provide the actual water demand and location of that demand. In addition to improved modeling capability, this demand data will enable Utility personnel to make adjustments on SCADA equipment that will improve water system operational efficiency.

Demand-Controlled Pumps: Saving water, time and money

by Dave Grieshop, Reality LLC, Sierra Vista, AZ

Hot water may come out of a faucet or showerhead, but it takes a plumbing system to get it to you. Regrettably, the vast majority of plumbing systems in the 75 million owner-occupied homes in the United States today are rather inefficient when it comes to delivering hot water.

This article reports on 11 of more than 130 homes in the Sierra Vista area that installed demand-controlled pumps (DCP) via a 2013 grant rebate program under the auspices of the Cochise Water Project, a not-for-profit 501(c)3 entity. These pumps meet IAPMO Material and Property Standard PS 115-2007, “Hot Water On-demand or Automatic Activated Hot Water Pumping Systems”.

DCPs have been around for two decades or so. They fundamentally do three things. First, they operate only when the homeowner activates the pump from any location in the home with an activation switch. Second, the DCP delivers hot water by priming the hot side from the water heater’s trunk line to the most distant fixture (sink) and uses the cold side of the trunk line to return ambient water back to the water heater – with no loss of water while the DCP is running. (Think of it as moving the water heater close to any fixture.) Third, the DCP automatically shuts off when it senses a 5 to 7 degree rise in temperature at the pump’s thermistor – about 2 to 5 feet from the hot water stub out. In other words, no hot water gets past the pump. The DCP is really a “fire and forget” pump activated by the homeowner when hot water is needed. Normally the DCP is installed under the sink at the most distant fixture from the water heater, using the existing hot and cold stub-outs under that sink. Once the DCP is installed and power is provided for the first time in the life of a home’s existing plumbing system, a loop is formed from the water heater to the most distant fixture and back to the water heater. This newly formed loop, incorporating the DCP, is the key to avoiding waiting for hot water and wasting water that otherwise would go down the drain! (For more detailed information on how a DCP works, visit www.gothotwater.com.)

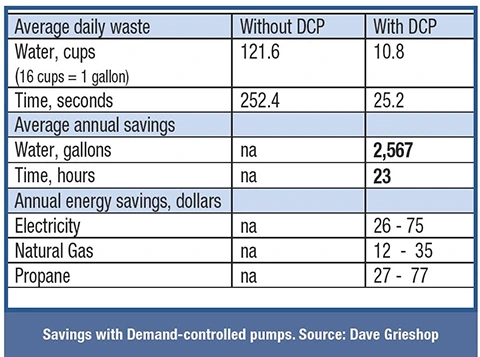

To calculate the impact of the DCPs on the 11 homes in which they were installed, data on wasted water and wasted time were gathered. Four daily demands for hot water were posited: three at the kitchen sink and one at a master bathroom fixture. In reality this is a very low estimate of demand that makes the calculations conservative. Wasted water and wasted time data were collected by homeowners when using their DCP and not using their DCP. The data reported are behavioral, not scientific, yet are real. As expected, the data had notable variances. The table shows the daily and annual results plus annual inferred energy savings due to water saved via a DCP. While water, time and energy savings were expected with a DCP installed, the magnitude of these savings was greater than anticipated. Energy costs used in the savings calculations were based on average Arizona costs for spring 2014 as calculated by the DOE’s Energy Information Agency.

In multiple surveys of homeowners who installed DCPs, 100 percent said they would do it again. When asked why, the universal answer was “the convenience” provided by the pumps. One homeowner made this comment about their pump: “It’s the best thing we have done in our home in 30 years.”

Homeowners might also want to consider this demand-controlled pump in their homes, given where we live in the Desert Southwest. Water is a precious commodity and should be used as efficiently as possible with convenience and reduced energy expenses as a bonus. Visit www.thecochisewaterproject.com for more information.